Maximum pumping capacity

(nominal) |

: |

3.0 m3/hour (as the fluidity material) |

Production |

: |

0.2 to 2.5 m3/hour or 3.33 liters (0,87 galons) to 41.66 liters (11 galons) per minute (test with no additive mortar dash labor)

0.2 to 3.0 m3/hour or 3.33 (0,87 galons) to 50 liters (13,2 galons) per minute (test with trace labor with mortar additive)

pumping and projection:

- roughcast (light plaster): +/- 600m2/hour = 4.800m2/day (can reach 6.000m2/day)

- plaster : +/- 100m2/hour = 800m2/day (can reach 1.000m2/day)

* average values, which may vary according to the composition of the mass used, plasticity of the mass, physical and logistical structure of the work, pumping height, hose length, etc.

|

Particle size |

: |

for pumping: up to 1cm3 to 10% (no damage to the pump)

projection: up to 6 mm3 to 10% (no damage to the pump) |

Range (without loss of efficiency) |

: |

- Vertically above: tested up to 20 meters (65,61 feet)

- Vertically below: tested up to 60 meters (196,85 feet)

- Horizontal: tested up to 40 meters (131,23 feet)

- Tests with trace workforce with plasticizer additive

- Pumping and / or projection with a particle size above 6 mm3 without additive presented clogging risks of mass hose.

- Mortar made on site without grading balance as recommended (different particle sizes, use of lime, plasticizers additives) can cause clogging of the mass hose |

Spraying pressure |

: |

Air:

- max: 140 psi (9,65 bar)

- min: 100 psi (6,89 bar)

Plaster:

- max: up to 14 kgmf/cm2 (199,12 psi / 13,72 bar)

(as the fluidity material) |

Transport hose |

: |

20 meters (65,61 feet) with an internal diameter of 1 inch

- With quick couplings |

Air hose |

: |

20 meters (65,61 feet)

- With quick couplings |

Actuation |

: |

main motor: 3 HP, 220 Volts, three-phase

air compressor: 1 HP, 220 Volts, mono/bi-phase |

Output force on the main shaft |

: |

on 60 HP at 60Hz |

Pump power (displacement) |

: |

on 196 HP at 60Hz |

Power supply |

: |

1 wall outlet, 220 Volts - eletric breaker with 20 amps or higher (single-phase or two-phase without changes on the machine)

simple wiring diagram (no changes on the machine):

- 220 single-phase connection with phase + neutral

- 220 two-phase connection with phase + phase

- 220 three-phase connection with phase + phase

- 380 three-phase connection with phase + neutral

- 440 three-phase connection with phase + neutral

- 660 three-phase connection with phase + neutral

In all connections it is mandatory to ground connection |

Electric consumption |

: |

Main engine: 2.2 KWh

Compressor: 0.7 KWh

-------------------------------

Total: 2.9 KWh |

Noise levels |

: |

The machine |

|

|

|

- Stop connected.............................. |

: |

56 dB |

- Pump working................................ |

: |

70 dB |

- Compressor and pump working....... |

: |

85 dB |

In the projection gun |

|

|

|

- Pump plaster.................................. |

: |

65 dB |

|

- Projecting (full operational)............. |

: |

90 dB |

|

Consumables |

: |

- internal flexible piston

- Tip rubber projection gun

- Plaster transport hose

- High pressure air hose |

Control panel |

: |

- Master switch (on/off) - Master switch (on/off)

- Pilot light

- Compressor command button (on/off)

- Visual alarm indicator/sound

- Flow adjustment knob

- Pump power button (forward/reverse)

- Emergency button (full stop)

* Remote control (pneumatic) in the projection gun |

Preventive maintenance |

: |

Cleaning of suction and transport hoses

Cleaning the projection gun. |

Periodic maintenance |

: |

Pump cleaning

verification of electro-electronic components

|

Weight |

: |

approximately 138.5 kg (305,34 pounds) (full kit: +/- 202.5kg (446,43 pounds)) |

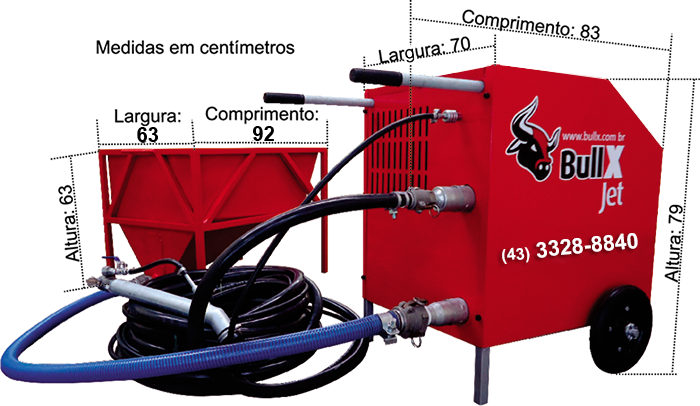

Dimensions |

: |

Machine:

- Length: 83 cm

- Width: 70 cm

- Height: 79 cm

Tank:

- Length: 102 cm

- Width: 64 cm

- Height: 63 cm |

Translating...

Altura = Height

Largura = Width

Comprimento = Length |

Delivery/shipping |

: |

FOB from Londrina-Paraná-Brazil (FOB=payment by customer) |

Cubage |

: |

Volume 1 (Machine) |

|

Volume 2 (Tank) |

| |

- Length: |

94cm (3,08 feet) |

|

|

- Length: |

110cm (3,60 feet) |

| |

- Height: |

97cm (3,18 feet) |

|

|

- Height: |

78cm (2,55 feet) |

| |

- Width: |

79cm (2,59 feet) |

|

|

- Width: |

78cm (2,55 feet) |

| |

- Weight (approx): |

160Kg (352,73 pounds) |

|

|

- Weight (approx): |

65Kg (143,3 pounds) |

| |

Total weight (approx): 225Kg (496,04 pounds) |

Note 1: weight difference considering packaging for land transport

Note 2: international shipping may vary the weight |

Warranty |

: |

One (1) year over any manufacturing defects

Normal wear consumables (see above) are excluded from the guarantee |

Known Issues

(And resolved) |

: |

- Dash labor (plaster made on site): transporting hose clogging since not met the recommendations in the plaster composition (as the user manual);

- Gypsum: transporting hose clogging (incorrect use of gypsum, plaster used with fast drying in 10 minutes - not suitable for projection);

- Power: constant activation of the alarm (incorrect connection, made in 110 Volts or supply amperage less than ideal for work: 20 amps or higher);

- Suction problems: false air into the suction hose (levers bad closed in the quick couplers) |

Known limitations |

: |

- Adhesive mortars (for tiling);

- Liquid petroleum-based;

- Grout (thin concrete) made on site;

- Concrete;

- Fast-drying gypsum. |

Machine composition |

: |

1 pump (internal)

1 air compressor (internal)

1 flexible piston (installed and ready to work)

20 meters (65,61 feet) transport hose with quick couplings

20 meters (65,61 feet) air hose with quick couplings

1 long gun projection

2 rubber tips for projection gun

1 electrical control cabinet (internal)

1 mass tank

2 meters (6,56 feet) pickup hose with quick couplings

|